Purpose-Built Ship: A New Wave of Maritime Innovation

The marine industry is witnessing a paradigm shift in craft design and construction. Gone are the days of multi-purpose ships attempting to fulfill various roles with compromised efficiency. The advent of purpose-built freighters marks a revolutionary approach to addressing definitive seafaring challenges and operational requirements. The task-definite boats are meticulously engineered to excel in their appointed functions, whether it be deep-sea research, offshore wind farm maintenance or specialized cargo transport.

Innovative Design and Cutting-Edge Technology

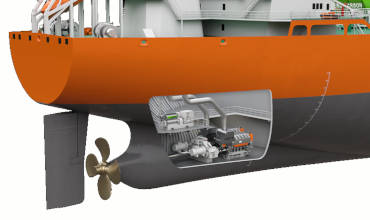

At the heart of this revolution lies the fusion of innovative arrangement principles and cutting-edge progress. Naval architects and seagoing engineers are pushing the boundaries of craft building, incorporating advanced materials, propulsion systems and digital equipments to create vessels that are not only highly efficient but also ecologically sustainable. From hull shapes optimized for specific sea conditions to integrated automation systems that enhance practical safety and bring down crew requirements, these specially made crafts represent the pinnacle of seafaring engineering.

Economic and Environmental Benefits

The shift towards task-specific boats brings forth a myriad of economic and recyclable advances. By tailoring freighters to specific operations, companies can significantly reduce operating prices, improve fuel efficiency and minimize environmental impact. Moreover, such specialized vessels often require smaller crews, leading to lower labor costs and enhanced safety protocols. As the maritime industry faces increasing pressure to diminish its carbon footprint, made-to-order crafts are paving the way for a more sustainable and efficient future in global shipping and seagoing operations.